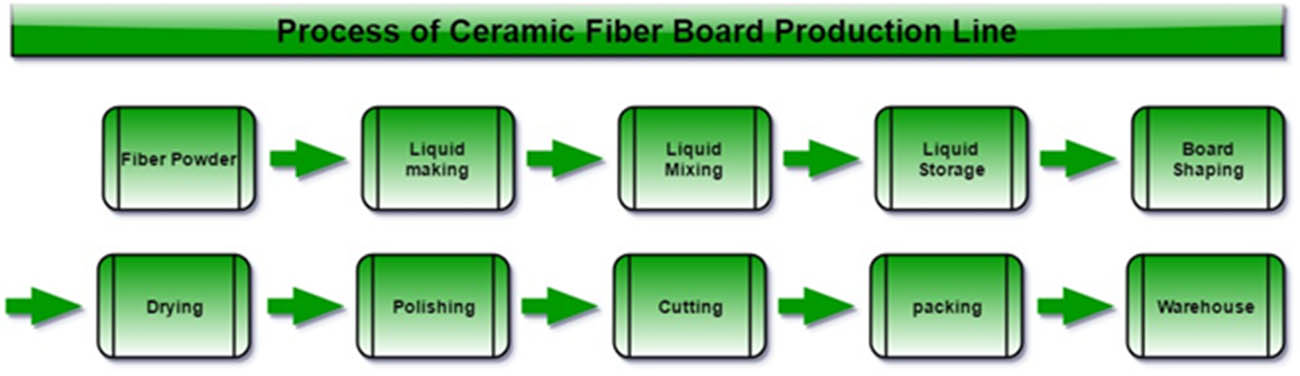

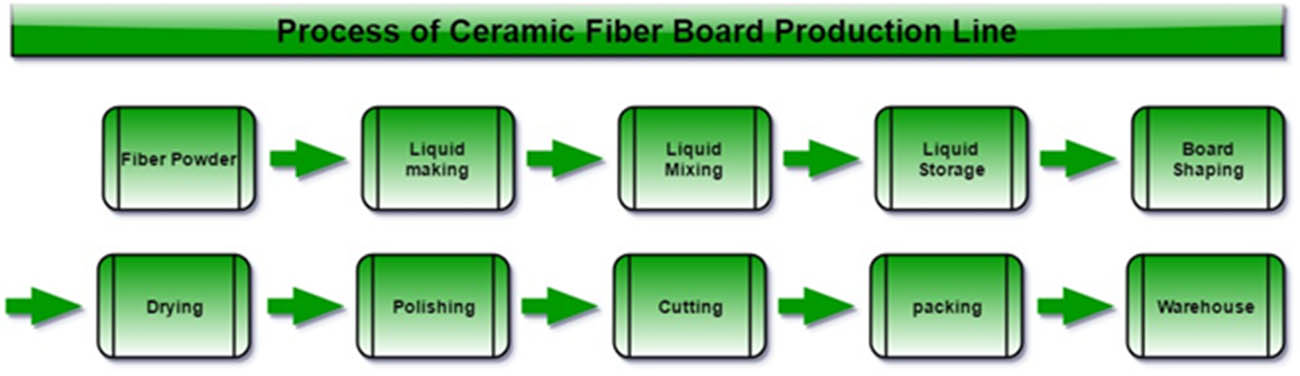

With development of industrial furnace lining construction, more and more customers prefer to install ceramic fiber board as thermal insulation material due to its excellent characteristic of smooth surface, low thermal conductivity and low shrinkage. It has been proved that heat insulation function of ceramic fiber board is better than regular rock wool board. There is no doubt that ceramic fiber board will became the substitute for rock wool board in the near future as thermal insulation linings will greatly influence the life time of industrial furnaces. Following contract signing, equipment design, equipment manufacturing, and goods delivery,Group will continue to provide a complete technical support to ensure the equipment to reach designed capacity covering supervision of installation and commissioning as well as training for customer's operation workers. As a responsible supplier, will keep close contact with customer to solve any problem during equipment operation.

With development of industrial furnace lining construction, more and more customers prefer to install ceramic fiber board as thermal insulation material due to its excellent characteristic of smooth surface, low thermal conductivity and low shrinkage. It has been proved that heat insulation function of ceramic fiber board is better than regular rock wool board. There is no doubt that ceramic fiber board will became the substitute for rock wool board in the near future as thermal insulation linings will greatly influence the life time of industrial furnaces. Following contract signing, equipment design, equipment manufacturing, and goods delivery,Group will continue to provide a complete technical support to ensure the equipment to reach designed capacity covering supervision of installation and commissioning as well as training for customer's operation workers. As a responsible supplier, will keep close contact with customer to solve any problem during equipment operation. Products Details

With development of industrial furnace lining construction, more and more customers prefer to install ceramic fiber board as thermal insulation material due to its excellent characteristic of smooth surface, low thermal conductivity and low shrinkage. It has been proved that heat insulation function of ceramic fiber board is better than regular rock wool board. There is no doubt that ceramic fiber board will became the substitute for rock wool board in the near future as thermal insulation linings will greatly influence the life time of industrial furnaces. Following contract signing, equipment design, equipment manufacturing, and goods delivery,Group will continue to provide a complete technical support to ensure the equipment to reach designed capacity covering supervision of installation and commissioning as well as training for customer's operation workers. As a responsible supplier, will keep close contact with customer to solve any problem during equipment operation.

With development of industrial furnace lining construction, more and more customers prefer to install ceramic fiber board as thermal insulation material due to its excellent characteristic of smooth surface, low thermal conductivity and low shrinkage. It has been proved that heat insulation function of ceramic fiber board is better than regular rock wool board. There is no doubt that ceramic fiber board will became the substitute for rock wool board in the near future as thermal insulation linings will greatly influence the life time of industrial furnaces. Following contract signing, equipment design, equipment manufacturing, and goods delivery,Group will continue to provide a complete technical support to ensure the equipment to reach designed capacity covering supervision of installation and commissioning as well as training for customer's operation workers. As a responsible supplier, will keep close contact with customer to solve any problem during equipment operation. Featured Products

-

Discover Bio-soluble Fiber Vacuum Shaped Products from our Factory | Affordable & Top Quality

-

Factory Direct Supply: High-Quality Ceramic Fiber Bulk for Optimal Insulation

-

Bio-soluble Fiber Vacuum Shaped Product

-

Bio-soluble Fiber Bulk

-

Get High-Quality Ceramic Fiber Paper with Our Factory's Production Line

-

Factory Direct Bio-Soluble Fiber Paper for High Heat Insulation

-

Bio-soluble Fiber Module

-

Ceramic Fiber Module Manufacturer: High-Quality and Customizable Solutions

-

Discover Durable Bio-Soluble Fiber Paper Solutions from our Factory

-

Get Quality Ceramic Fiber Boards - Factory Direct Production Line

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours